At Frank Miller Lumber, we’ve always been committed to providing top-quality lumber and unparalleled customer service. Over the years, we’ve grown and evolved, continually striving to meet and exceed the expectations of our valued customers. In recent weeks, we have slowly rolled the rebranding of our retail store to Frank Miller Lumber Fine Woods. This change reflects our dedication to enhancing our product offers and signifies our commitment to becoming your premier destination for the finest woods and woodworking materials.

Expanded Product Offerings

With our rebranding, we are excited to introduce an expanded range of products catering to various woodworking needs. Whether you are a professional carpenter, a dedicated hobbyist, or someone embarking on a DIY project, you will find an extensive selection of premium exotic hardwoods, locally made finishes, handcrafted gifts, and much more.

Our inventory includes:

Exotic Hardwoods: Explore rare and unique species from around the world, such as zebrawood, purpleheart, and padauk, ideal for crafting one-of-a-kind pieces.

Domestic Hardwoods: Choose from the finest quality oak, cherry, walnut, maple, and more, all sourced sustainably.

Specialty Plywood: Choose from various high-grade plywood, ideal for structural and decorative applications.

Live Edge Slabs: Experience the natural beauty of live edge slabs, each uniquely shaped and perfect for creating stunning tables, countertops, and other statement pieces.

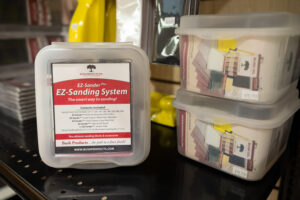

Woodworking Accessories: Explore a range of finishes, sandpaper, and Bush Oil Product finishing kits to easily complete your projects.

A New Look, the Same Trusted Service

While our name and logo may have changed, our dedication to serving our customers remains unwavering. We are still the same family-owned business you have come to know and trust, now with a renewed focus on providing an even better shopping experience. We invite you to visit Frank Miller Lumber Fine Woods and experience the transformation yourself.

Thank you for your continued support and trust in Frank Miller Lumber Fine Woods.

For more information, please contact us at 765-964-7705 or ctimmerman@frankmiller.com.