When I talk to architects and designers about using American hardwoods I am usually battling preconceived notions of how our forest resource is managed in the United States. The destruction of the rain forests taints the picture of sustainable American hardwoods. The media has done a great job of convincing people that when we use a tree we are killing the planet in some small way. The information I present involves a great deal of counter intuition.

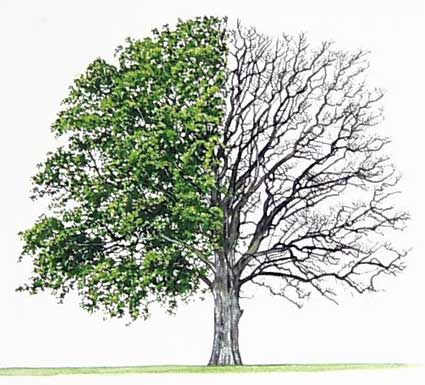

For example, due to societal conditioning, it seems counter intuitive to suggest that the more you utilize our forest resource, the healthier the forests become. It is also counter intuitive to say that there is twice as much hardwood growing now than there was 50 years ago in America. Another part of my presentation that seems counter intuitive is that when it is time to harvest hardwood trees from a particular stand of hardwoods, the tree chosen is the most beautiful mature tree. To many this feels like killing Bambi.

First, the destruction of the rain forest has far more to do with conversion of the forest to agricultural purposes than random timber harvest. Second, it is through selection harvest that we keep our forests healthy. The more we systematically remove the mature trees, the more new growth is encouraged. When we harvest trees at their peak of life, we capture the carbon that the tree has been dutifully absorbing all of its life. Once that tree has been rendered into boards and then into a piece of furniture, the carbon is captured forever.

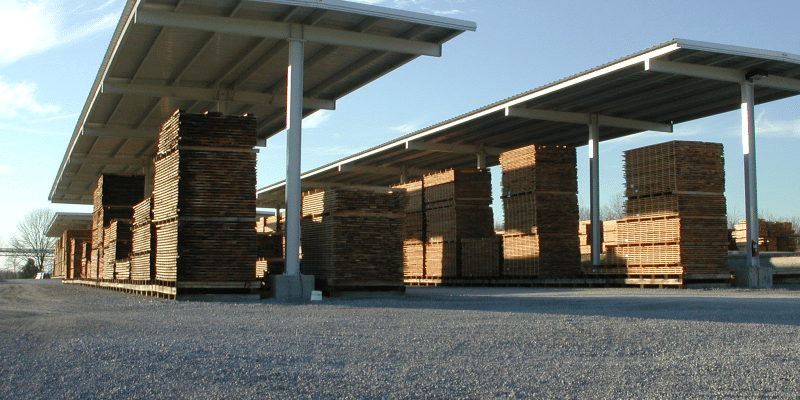

It seems counter intuitive that the sound of a chain saw in a mature stand of American hardwoods is actually indicative of healthy forest management. Even more counter intuitive that American hardwood can ship from Indiana and arrive in Australia as a carbon negative building product. This is due to the amount of carbon stored in the wood versus the carbon footprint of the sawmilling, drying and transportation on of the wood.

The good thing about dealing with all of this counter intuitive information is that it is all empirically verifiable. I tell my audiences that they all have a way to assess the health of America’s forests – Google Earth™. Just pick any state in the eastern US and fly across it and you will see miles and miles of healthy hardwood forests. If I were one to put bumper stickers on my car, mine might read: “Save The Planet – Use More American Hardwoods.”